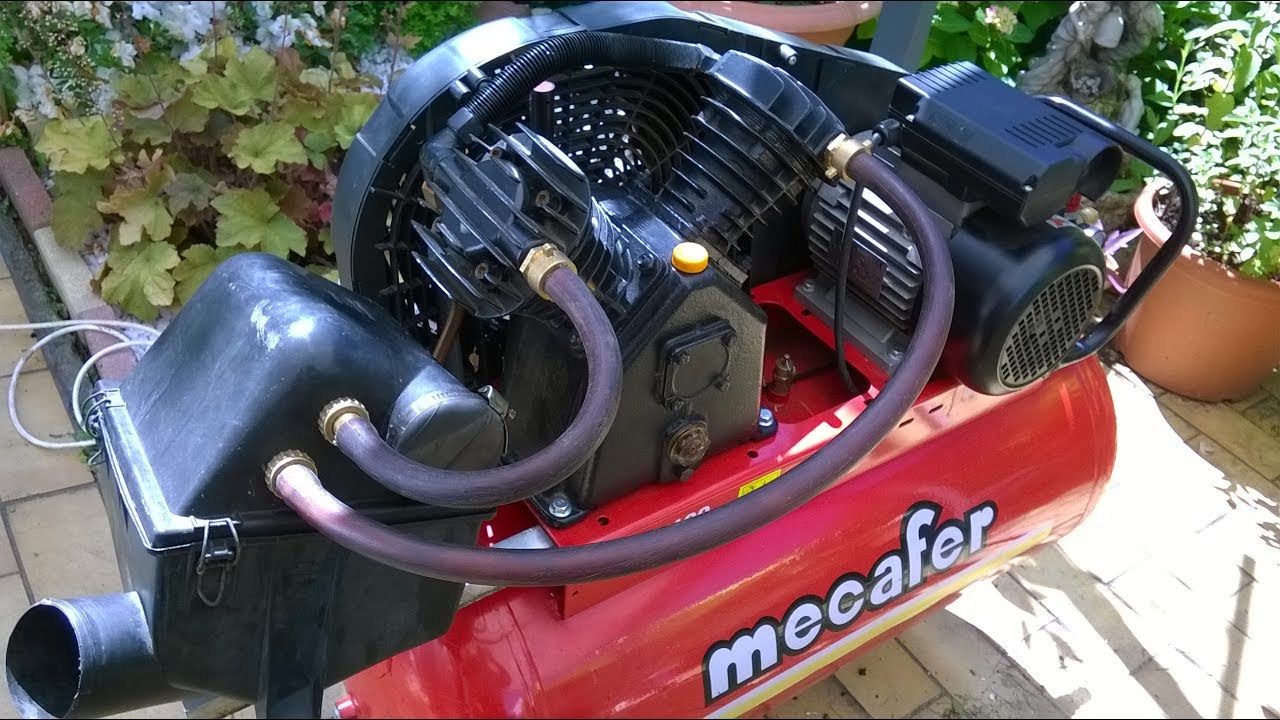

Air Compressor Noise Suppressor

HVAC Noise Diagnosis & Cure How to Evaluate Air Conditioner / Heat Pump Compressor, Air Handler, Ductwork Noises. POST a QUESTION or READ FAQs about air conditioning or heat pump system equipment or control or ductwork noises: cause, significance, cure. This article offers suggestions on how to reduce air compressor noise, such as wearing hearing protection, using an enclosure or installing a muffler.

If you are Googling “ Air Compressor Noise“, “ Compressor Making Weird Noise” or “ Air Compressor Making Rattling Noise“, this post should help clarify why and offer solutions to get your air compressor working quieter again. While reciprocating air compressors aren’t known for being whisper quiet, if they suddenly are making a lot more noise there might be a problem. Check these four common issues that might cause new and louder air compressor operation.Why Air Compressors Make Loud NoisesThere are a few reasons why air compressors make loud noises. Sometimes it is a really simple problem that takes less than a minute to fix while others might require repair.

Loose MountingWhen air compressors are installed they are leveled on a sturdy base and anchored in place. Sometimes vibration pads get out of place, become worn, or go missing. The bolts holding the air compressor down can also become loose and might just need to be tightened. Parts Are LooseIf the parts inside your air compressor are loose, it will make a lot of noise.

You should check to see if your cooler, pulleys, clamps, flywheel, belt, or any other accessories are loose and need to be tightened. Crankcase IssuesYour crankcase may be the source of the noise and might need oil, new bearings, or might need to be replaced entirely. Check to make sure its bolted in tightly and if that doesn’t fix it, call for service. There are times where you might just need to fill up the crankcase oil, and others where you’ll have to replace the crankcase itself. Compressor Is VibratingIf your compressor is excessively vibrating there’s a chance you just need to tighten some bolts or tighten a belt.

Air Compressor Noise Suppressor Systems

Other problems that cause vibration include misaligned flywheels and pulleys, the compressor not being mounted properly, or a bent crankcase. Piston IssuesIf the pistons are dirty there is a chance they can hit the valve plate. To fix this you will need to take the cylinder head out, ensure it’s clean, and then put it back in with a new gasket.While many air compressors are either installed outside the shop or in a semi-remote corner if the noise gets out of hand it can become difficult to work around. Not only will it be a nuisance but excessive noise is a sign that something isn’t right with your air compressor and something needs to be repaired. It’s best to catch problems when they are small to avoid costly and extensive repairs or needing to completely replace your air compressor. AC Compressor Noises That Need Immediate AttentionThere are different noises that come out of air compressors that you need to listen for. Each of them point to different possible air compressor repair options.

Read through our list of noises your air compressor might be making and get in touch with our air compressor technicians for repair. Bubbling or HissingIf you hear bubbling or hissing it points to a refrigerant leak. If it is just bubbling and hissing the leak is smaller and likely in the lines. If it is louder and just hissing the leak is likely larger. Either way if your system is losing refrigerant it will use more energy and eventually stop working. Rattling NoisesIf you hear a rattling sound it can point to AC compressors mounts that have become loose. The internal mounts hold the motor and if they are loose it is actually free to move around inside the compressor can.

Banging NoisesIf you hear a banging in your AC compressor there is likely a loose component or part such as a piston pin or connecting rod. In many cases the cost of repairing this issue is so close to or higher than buying a new one that they are simply replaced. Humming NoisesIf your AC compressor makes a humming noise or is hard to start there’s a chance it is low on oil. A humming noise can also point to a bad starting capacitor. If your compressor just hums but doesn’t start there is a chance that the compressor motor has seized. Clicking NoisesWhen you hear clicking noises in your ac compressor the cause is likely the relays or controls that are trying to initiate parts of your system, but fail and just click.

To repair this issue some relays might need replacing or the control unit might need repair or replacement. Hissing NoisesWhen your system is hissing loudly and sounds like screaming it a serious sign of excessive pressure.

If you hear anything that resembles this, you need to call for AC compressor servicer immediately. Excessive pressure puts strain on all the components in your system and can lead to leaks. Rumbling or TickingMost of the other sounds we’ve listed are specific problems with or in the AC compressor. If you hear a rumbling or ticking sound there may be other parts of your HVAC system which have come in contact with your AC Compressor and are making these noises.Need Help Repairing Air Compressor Noises?Have an air compressor that making loud noises or rattling noises in Arizona?

Willing Service Corporation offers services to facility owners in Phoenix, Arizona. If you need help getting your air compressor quieter again give us a call today at. We also sell replacement if your air compressor is beyond repair.Call.

DB Noise Reduction will evaluate the configuration of your compressor, noise level requirements, temperature limits, pressure rating and overall system in selecting the proper compressor silencer for the job.Our compressor silencers offer:. Maximum sound absorption. Minimal airflow restriction and pressure drop. Noise attenuation to meet application needsReciprocating compressors exhibited destructive low frequency pressure pulsations and noise.

Therefore, in most cases, it is essential to use a reactive inlet compressor silencer to dissipate the pulse energy. If high mid-to-upper band noise is also a problem, then a reactive-absorptive compressor silencer should be used to address both concerns.When noise radiating from downstream piping is a problem on reciprocating compressors, reactive or reactive-absorptive discharge compressor silencers will be necessary as well.For centrifugal compressors, impellor blade passage frequency is usually the noise concern requiring treatment. Absorptive silencers are usually the right silencer for the job for open inlet and discharge silencers on centrifugal compressors.

However, when low frequency noise is also a problem, reactive-absorptive silencers may be appropriate solution.